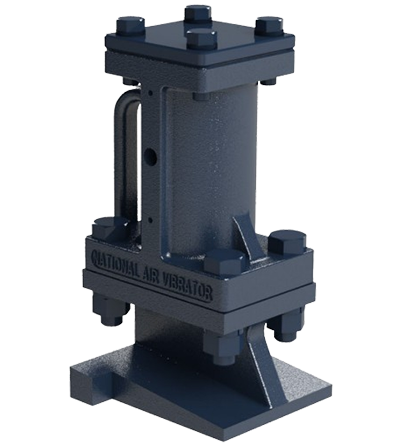

NAVCO Overhead Railcar Shaker Industrial Overhead Railcar Shaker

Heavy-duty Overhead Railcar Shaker designed to improve material flow and reduce unloading time in open-top hopper railcars.

Engineered for the Heaviest and Most Demanding Railcar Unloading Applications

The NAVCO Overhead Railcar Shaker is designed specifically for unloading open-top hopper railcars in industrial environments where material flow problems are common. Built for harsh operating conditions, this system delivers powerful vibration to promote consistent material discharge where standard railcar vibrators are ineffective. Whether dealing with frozen coal, moisture-laden aggregates, compacted fines, or sticky minerals, the NAVCO Overhead Railcar Shaker keeps bulk materials moving in the most challenging applications.

Heavy-Duty Construction for Long Service Life

The shaker is manufactured using heavy steel components and a structurally reinforced frame to withstand continuous industrial use. With minimal moving parts and robust mechanical assemblies, this equipment is engineered to deliver a long, productive operating life in the toughest environments, including outdoor unloading yards, power generation plants, mining operations, and material terminals.

Reliable Performance Across Many Industries

The NAVCO Overhead Railcar Shaker is widely used by industries that depend on the timely movement of bulk materials. This includes Aggregates, Power Generation, Mining, Asphalt Production, Steel, Cement, and Refining. Its reliability and performance make it the preferred solution where consistent railcar unloading is essential.

Improved Material Flow in Difficult Conditions

The system produces a controlled vibration response in the railcar that breaks up bridging, rat-holing, compaction, and material hang-ups. From coal and coke to limestone, ores, and other bulk materials, the shaker ensures that even stubborn or moisture-rich material continues to flow freely.

Reduce Unloading Time and Increase Efficiency

NAVCO Overhead Railcar Shakers significantly reduce the time required to unload open-top hopper railcars. By eliminating material blockages and ensuring uniform flow, operators experience faster cycle times and improved productivity across unloading operations.

Eliminate Costly Carryback

Stuck material left inside railcars can lead to contamination, loss of usable product, and carryback charges. The Overhead Railcar Shaker is designed to completely empty the railcar by dislodging compacted or stuck material. This reduces operating costs and eliminates the need for manual cleaning.

Enhance Worker Safety

Manual scraping and entry into railcars present significant safety risks. By removing material through controlled vibration, the NAVCO Overhead Railcar Shaker eliminates the need for workers to enter railcars, reducing injury risk and supporting safer unloading practices.

Designed for Continuous and Demanding Use

The shaker system is suitable for facilities operating long shifts or around-the-clock schedules. Its durable construction, mechanical resilience, and low-maintenance design allow for reliable operation during extended use in demanding industrial environments.