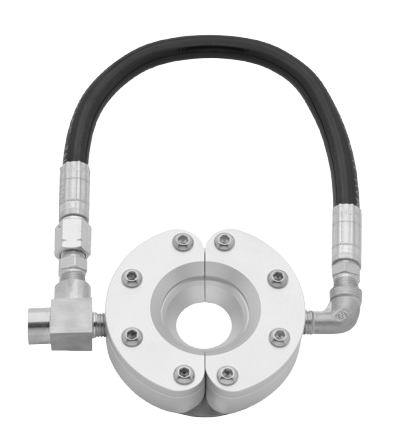

Stainless-steel Airmasters Machine Tool Cooler (AIR-MTC) designed for dry machining—replacing toxic mist systems with clean, powerful vortex cooling. Ideal for drilling, milling, grinding and high-heat machining applications

Airmasters Machine Tool Coolers (AIR-MTC) are advanced dry machining cooling systems designed to replace traditional mist, coolant and lubricant systems. They eliminate oily residue, reduce contamination and provide powerful spot cooling using vortex technology—allowing clean, efficient and eco-friendly machining.

Manufactured entirely from durable stainless steel, including the internal vortex tube (with brass generators), the AIR-MTC cooler withstands high temperatures, heavy-duty machining environments and long-term industrial use. With no plastic components, no electricity and no moving parts, the system is virtually maintenance-free and highly reliable.

Airmasters Machine Tool Coolers increase machining speeds, extend tool life and improve surface finish by delivering continuous cold air directly to the cutting zone. They are available in multiple capacities—15, 25, 30 and 40—and offered in two versions:

• Single outlet for drilling, grinding and point cooling

• Dual outlet for milling, sawing and large-area heat generation

The included magnetic base ensures secure mounting during high-vibration machining operations. Recommended inlet air pressure: 5 to 7 Bar.

Applications

– Tool sharpening

– Grinding

– Milling

– Drilling

– Band sawing

– Plastic machining

– Routing

– Chill roll cooling

Single-point kits are ideal for focused cooling, while dual-point kits cover wider areas. A single-point system can be upgraded to dual-point simply by adding the dual hose kit.