Vortex Cabinet Cooler Manufacturers

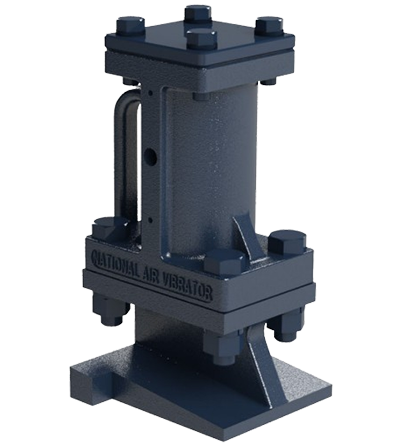

ACE Flow Konzepts Pvt Ltd is the Productive Vortex Cabinet Cooler Manufacturers in Maharashtra. The unit is constructed from robust materials, such as stainless steel (SS304 & SS316L), for long-term performance even under severe conditions. The unit has a compact design, is simple to install, and does not require the space or infrastructure that traditional air conditioning systems typically require. The cooler's energy efficiency not only renders it cheap but also eco-friendly because it reduces energy consumption by leveraging only compressed air. In addition, the lack of external power sources reduces operational costs as well as installation complications.

Vortex Cabinet Cooler Suppliers in Maharashtra

- Minimal maintenance with no moving parts.

- Compact and easy to install on existing cabinets.

- Energy-efficient operation for reduced costs.

- Adjustable cooling levels for customized performance.

- Ensures uninterrupted operation and extended equipment life.

Vortex Cabinet Cooler in India

With us, you get the Adaptive Vortex Cabinet Cooler in India. The system does not rely on moving parts, refrigerants, or electricity and is thus highly reliable and low in maintenance. It uses compressed air to create cold air and, simultaneously, it expels the hot air from the enclosure. The Cabinet Cooler, as soon as it is installed, starts to maintain a safe and constant temperature inside the cabinet. This keeps critical electronic equipment operational, protecting your systems and machinery from costly downtime due to overheating. The Cabinet Cooler maintains heat-sensitive electronics, control panels, and equipment at their optimum temperature range, thus preventing overheating and protecting them from excessive heat damage. The system is particularly handy in locations where high temperatures, dust, or contaminants can cause equipment failure.

Vortex Panel/ Cabinet Cooler

Vortex Cabinet Cooler are not only used to cool the electrical panel, but they are also used to purge air and maintain a positive pressure inside the panel. Once the positive pressure is maintained inside the panel, it will not attract any dirt or dust inside the panel which will keep the panel clean and rust free for a very long time.

Advantages

- Low in cost

- Compact

- SNo CFC’s

- Fast installation

- Stabilize enclosure temperature and humidity

- Virtually maintenance free (No Moving Parts)

- Mounts in a standard electrical knockout

- Stops heat damage and nuisance tripping

- Eliminates fans and filters

- Prevents dirt contamination by keeping enclosure at positive pressure

- Units applicable to all environments including high temperature to 200ºF

Panel Cooler Selection

- Selecting the right Panel Cooler or Cabinet Panel Cooler or Cabinet Cooler or Air Conditioner for your panel is very important, since the wrong model can waste lot of air and not be effective. To understand which model is suitable for your panel or application, a calculation for air consumption in CFM for your panel is required to be done. For this calculation, the size of the panel and heat generated inside the panel is to be known. According to this information, the appropriate model can be selected.

- Panel Cooler are available with or without Digital Temperature Controller with sensor control. When constant cooling and a constant positive purge is required, we recommend the continuous operating version without the thermostat and solenoid valve. The cooling effect can be controlled by adding a regulator in line to reduce pressure for reduced cooling when it is not required and to conserve energy.

- Systems utilizing a digital temperature controller with sensor and solenoid valve save air by activating the Panel Cooler only when the internal temperature reaches a critical level. The digital temperature controller is factory set at 28°C but can be readjusted on site. Digital temperature controller with sensor and solenoid valve systems are recommended where the heat load can fluctuate (such as for frequency drives) and where a continual purge is not required. The digital temperature controller with sensor and solenoid “package” can also be added at a later date to a continuous system.

| Type | Model | Air Consumption | CapacityWatt (BTU/hr) |

Sound level |

| IP 54 | AIR-CC2-IP54 | 2 SCFM | 42(145) | 75 dB(A) |

| IP 54 | AIR-CC4-IP54 | 4 SCFM | 85(290) | 75 dB(A) |

| IP 54 | AIR-CC8-IP54 | 8 SCFM | 170(580) | 75 dB(A) |

| IP 54 | AIR-CC10-IP54 | 10 SCFM | 214(730) | 78 dB(A) |

| IP 54 | AIR-CC15-IP54 | 15 SCFM | 322(1100) | 78 dB(A) |

| IP 54 | AIR-CC25-IP54 | 25 SCFM | 527(1700) | 78 dB(A) |

| IP 54 | AIR-CC30-IP54 | 30 SCFM | 615(2100) | 78 dB(A) |

| IP 54 | AIR-CC40-IP54 | 40 SCFM | 849(2900) | 78 dB(A) |

| IP 54 | AIR-CC50-IP54 | 50 SCFM | 1054(3600) | 81 dB(A) |

| IP 54 | AIR-CC60-IP54 | 60 SCFM | 1230(4200) | 81 dB(A) |

| IP 54 | AIR-CC70-IP54 | 70 SCFM | 1462(5000) | 81 dB(A) |

| IP 54 | AIR-CC80-IP54 | 80 SCFM | 1698(5800) | 81 dB(A) |

| IP14 | AIR-CC4-IP14 | 4 SCFM | 85(290) | 75 dB(A) |

| IP14 | AIR-CC8-IP14 | 8 SCFM | 170(580) | 75 dB(A) |

| IP14 | AIR-CC10-IP14 | 10 SCFM | 214(730) | 78 dB(A) |

| IP14 | AIR-CC15-IP14 | 15 SCFM | 322(1100) | 322(1100) |

| IP14 | AIR-CC25-IP14 | 25 SCFM | 527(1700) | 78 dB(A) |

| IP14 | AIR-CC30-IP14 | 30 SCFM | 615(2100) | 78 dB(A) |

| IP14 | AIR-CC40-IP14 | 40 SCFM | 849(2900) | 78 dB(A) |

| IP66 | AIR-CC104-IP66 | 4 SCFM | 85(290) | 75 dB(A) |

| IP66 | AIR-CC108-IP66 | 8 SCFM | 170(580) | 75 dB(A) |

| IP66 | AIR-CC110-IP66 | 10 SCFM | 214(730) | 78 dB(A) |

| IP66 | AIR-CC115-IP66 | 15 SCFM | 322(1100) | 78 dB(A) |

| IP66 | AIR-CC125-IP66 | 25 SCFM | 527(1700) | 78 dB(A) |

| IP66 | AIR-CC130-IP66 | 30 SCFM | 615(2100) | 78 dB(A) |

| IP66 | AIR-CC140-IP66 | 40 SCFM | 849(2900) | 78 dB(A) |

| IP66 | AIR-CC110-316L-IP66 | 10 SCFM | 214(730) | 78 dB(A) |

| IP66 | AIR-CC115-316L-IP66 | 15 SCFM | 322(1100) | 78 dB(A) |

| IP66 | AIR-CC125-316L-IP66 | 25 SCFM | 527(1700) | 78 dB(A) |

| IP66 | AIR-CC130-316L-IP66 | 30 SCFM | 615(2100) | 78 dB(A) |

| IP66 | AIR-CC140-316L-IP66 | 40 SCFM | 849(2900) | 78 dB(A) |