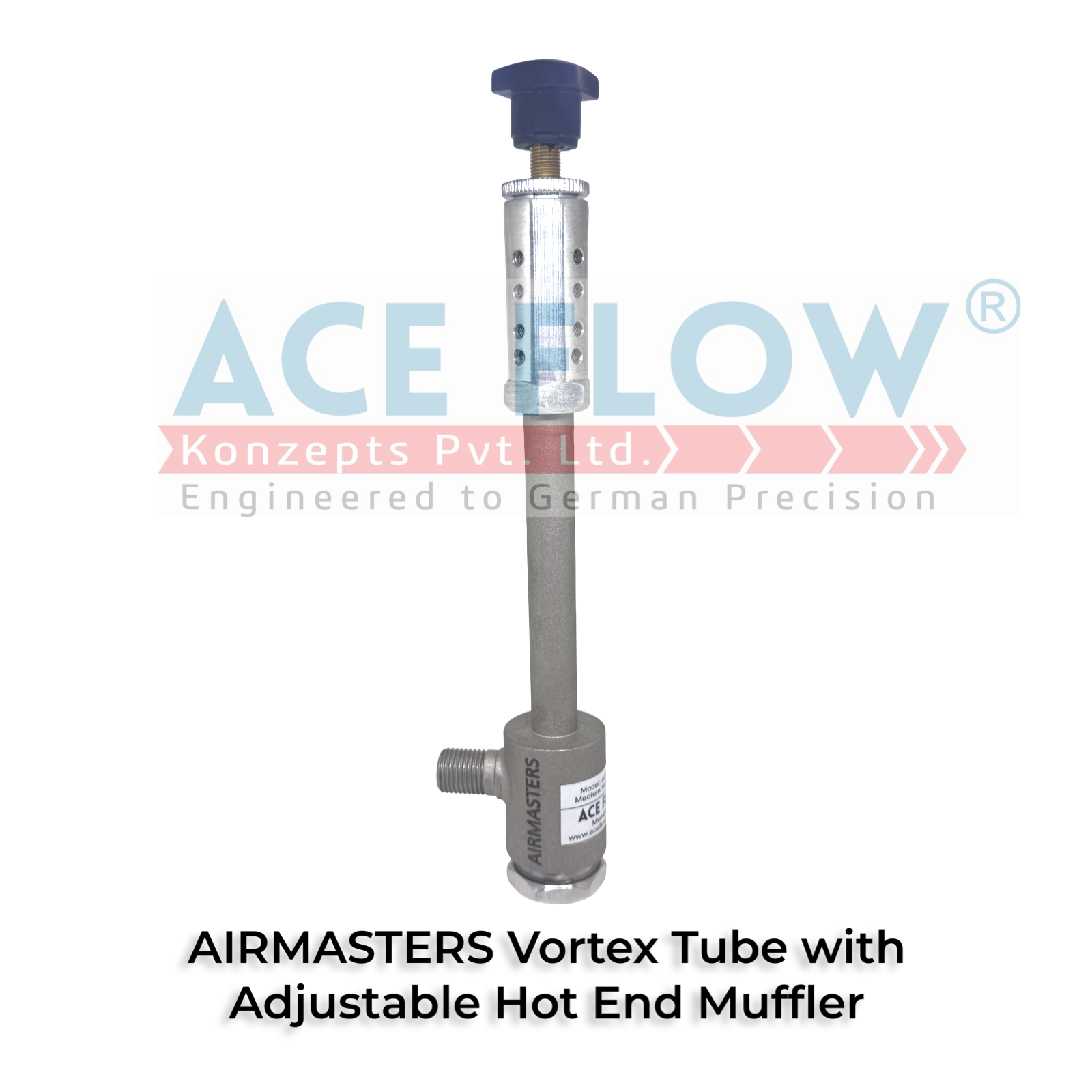

Airmasters Vortex Tube Manufacturers in India – High-performance compressed-air cooling solution for spot cooling, panel cooling, and industrial temperature control applications.

The Airmasters Vortex Tube is a durable and efficient cooling device designed for industrial environments where reliable temperature control is essential. It operates without mechanical wear, ensuring long service life and consistent performance. Powered entirely by compressed air, the vortex tube requires no electricity, making it ideal for hazardous, remote, or power-restricted locations. It can generate temperatures as low as –40°F, offering fast and effective cooling for tools, electronics, workspaces, and sensitive components.

Airmasters Vortex Tube in India

At ACE Flow Konzepts Pvt. Ltd, we offer the practical and high-performance Airmasters Vortex Tube in India. The device is known for its low maintenance, thanks to its simple internal design and absence of moving parts. Only occasional external cleaning is required to remove dust or contaminants. With a properly filtered compressed air supply, the vortex tube ensures trouble-free and long-term operation, reducing downtime and overall maintenance costs for industries.

How the Vortex Tube Works

Invented in 1930 by French physicist Georges Ranque, the vortex tube splits compressed air into cold air and hot air without using any mechanical parts.

-

Compressed air enters through a generator.

-

The air spins rapidly, separating into two streams—cold at one end, hot at the other.

-

An adjustable hot-end valve controls airflow volume and the cold fraction, allowing users to fine-tune the exit temperature according to their application.

Airmasters Vortex Tubes are available with adjustable or preset cold fractions, and feature interchangeable brass generators that help control airflow rates and temperature output. Generators are available in various capacities depending on compressed air requirements.

Available Sizes

The Airmasters Vortex Tube is available in multiple sizes:

-

Small: 2–8 SCFM

-

Medium: 10–40 SCFM

-

Large: 50–150 SCFM

Larger capacities are less commonly used due to higher energy consumption.

These vortex tubes can generate temperatures up to 100°F (56°C) below the inlet air temperature.

Advantages

-

No plastic components – brass generators for long life

-

No moving parts

-

Operates on compressed air – no electricity needed

-

Compact, lightweight, and portable

-

Cost-effective cooling solution

-

Superior design and stable performance

-

Maintenance-free operation

-

Durable stainless-steel and metal construction

-

Adjustable temperature range

-

Interchangeable generators

Applications

-

Cooling components and tools

-

Welding process cooling

-

Component drying

-

Electrical panel cooling

-

CNC system cooling

-

Setting hot-melt adhesives

-

Cooling ultrasonic welding horns

-

Cooling molded plastics

-

Electronic component cooling

-

Heat-shrink tube cooling

-

Preventing condensation inside electronics

-

PLC panels, relay panels, MCCs, system control cabinets

-

Workspaces where panel cooling is needed near operators

-

Laser housing cooling

-

Noise-sensitive industrial environments

Products Made Using Vortex Tube

-

Panel Cooler

-

Tool Cooler

-

Spot Cooler

Accessories

-

Air Filter (recommended)

-

Magnetic Base

-

Brass Generator

-

Hot End Silencer

-

Cold End Silencer

-

Modular Hose

| Model No. | SCFM | SLPM | BTU/Hr | Watts | Size |

| AIR-M2H | 2 SCFM | 57 SLPM | 145 BTU/Hr.” | 42 W | Small |

| AIR-M4H | 4 SCFM | 113 SLPM | 290 BTU/Hr | 85 W | Small |

| AIR-M8H | 8 SCFM | 227 SLPM | 580 BTU/Hr. | 170 W | Small |

| AIR-M10H | 10 SCFM | 283 SLPM | 730 BTU/Hr. | 214 W | Small |

| AIR-M15H | 15 SCFM | 425 SLPM | 1100 BTU/Hr. | 322 W | Medium |

| AIR-M25H | 25 SCFM | 708 SLPM | 1800 BTU/Hr. | 527 W | Medium |

| AIR-M30H | 30 SCFM | 850 SLPM | 2100 BTU/Hr. | 615 W | Medium |

| AIR-M40H | 40 SCFM | 1133 SLPM | 2900 BTU/Hr. | 849 W | Medium |

| AIR-M50H | 50 SCFM | 1370 SLPM | 3500 BTU/Hr. | 1025 W | Large |

| AIR-M75H | 75 SCFM | 2018 SLPM | 5200 BTU/Hr. | 1523 W | Large |

| AIR-M100H | 100 SCFM | 2700 SLPM | 6900 BTU/Hr. | 12022 W | Large |

| AIR-M150H | 150 SCFM | 4150 SLPM | 10.300 BTU/Hr. | 3018 W | Large |