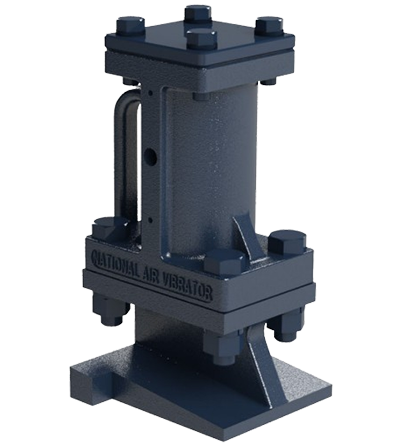

High-performance NAVCO Pneumatic Piston Vibrators designed for improving material flow in hoppers, bins, silos and chutes. Durable, low-maintenance and ideal for powders, grains, aggregates and bulk solids.

ACE Flow Konzepts Pvt Ltd supplies premium NAVCO Pneumatic Piston Vibrators in India, engineered to eliminate material buildup and improve flow of bulk solids in hoppers, bins, silos, chutes and other storage or handling systems. These vibrators use compressed air to generate powerful linear vibrations that help stubborn materials such as powders, grains and aggregates move freely without clogging.

Built for harsh conditions, NAVCO vibrators perform reliably in high-temperature, dusty and heavy-duty environments. Their simple construction ensures minimal maintenance, adjustable vibration intensity and long service life. By reducing material sticking and preventing flow blockages, NAVCO vibrators help minimize downtime, increase efficiency and eliminate the need for unsafe manual hammering or cleaning.

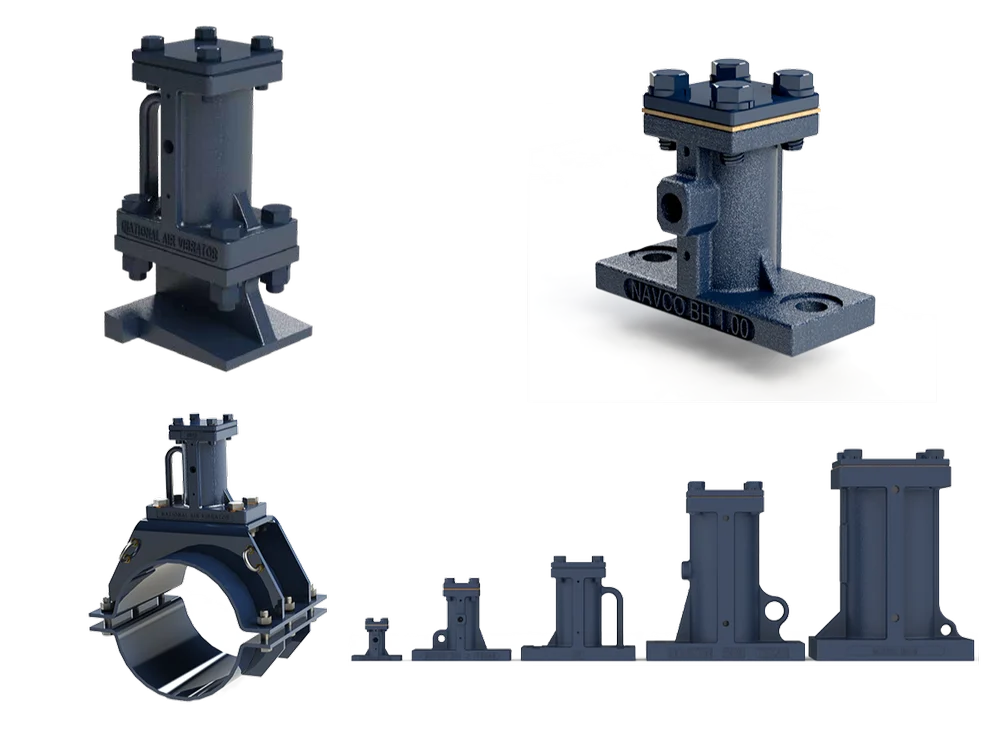

NAVCO Vibrator Models

NAVCO manufactures different types of pneumatic piston vibrators for specific flow characteristics:

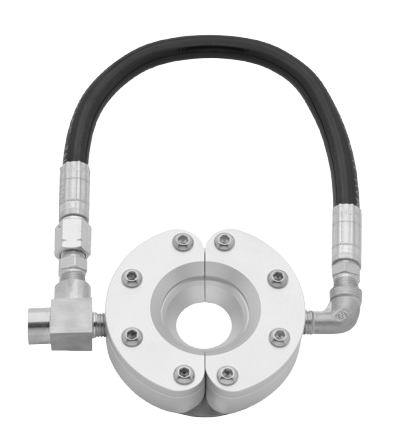

Impacting Type (IGO)

Produces high-amplitude repetitive impacts for tough, cohesive materials that resist flow. Excellent for emptying bins and breaking material bridges.

Silent Type (SGO)

Generates smooth sinusoidal vibration using air cushioning at both ends. Ideal for free-flowing or non-cohesive materials requiring gentle vibration.

Timed Impact Type (IGT)

Delivers one powerful impulse per cycle when triggered—ideal for controlled evacuation of hoppers and vessels with low noise and low air consumption.

BH – Bin Hopper Vibrators

NAVCO Bin Hopper Vibrators are available in 10 sizes for light to heavy-duty applications. Options include:

-

Tapped exhaust ports

-

Internal springs for horizontal mounting

-

Specialty coatings for corrosive or abrasive environments

Large BH units are suited for coal, ore and steel, whereas smaller units fit chemical, food, grain and pharmaceutical applications.

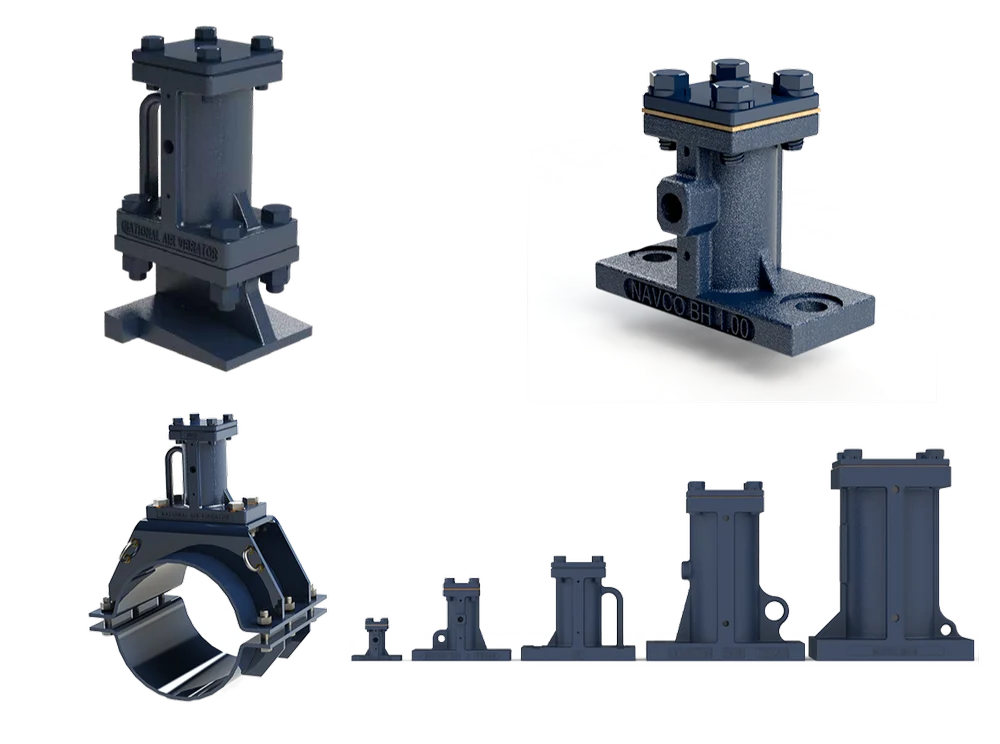

Accessories

– Specialty interior coatings

– Single / dual tapped exhaust

– Start springs

– Timers & control systems

– PLC / feedback-based automation

Mounting Options

– T-Slot Mount (flat hoppers)

– Channel Mount (curved hoppers)

– U-Mount (chutes & pipes, light duty)

– Slip Mount (portable use)

NAVCO’s vibration technology ensures consistent material flow, reduced operator intervention and long-term operational reliability across diverse bulk-handling industries.

| Model No | Frequency | Air Consumption | Sound Presuure Level | Sizing Criteria | |||||

| Impacting (VPM) | Silent (VPM) | Impacting (SCFM) | Silent (SCFM) | Impacting (dBA) | Silent dBA) | Hopper Capacity(cu. ft) | Wall thickness range (inches) | Weight (lb) | |

| BH-1 | 7250 | 3600 | 3.3 | 3.0 | 86 | 73 | 3 | 1/16”-1/8” | 3 |

| BH-1.25 | 5250 | 3150 | 4.2 | 4.0 | 87 | 67 | 3-7 | 1/16”-1/8” | 3 |

| BH-1.62 | 5100 | 2200 | 7.5 | 7.2 | 102 | 74 | 7-20 | 3/16”-1/4” | ” 18 |

| BH-2 | 4750 | 2100 | 8.3 | 8.3 | 106 | 73 | 20-50 | 3/16”-1/4” | 20 |

| BH-3 | 3400 | 1800 | 11.6 | 11.3 | 96 | 76 | 10-20 ton | 1/4”-3/8” | 50 |

| BH-4 | 2750 | 1400 | 18.2 | 18.2 | 110 | 83 | 50-100 ton | 3/8” – 1/2” | 105 |