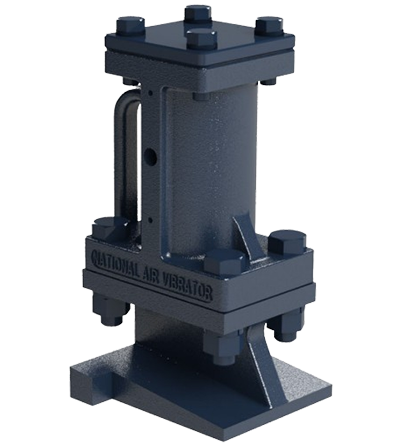

The High Flow Air Gun is a heavy-duty industrial blow-off tool designed for applications where standard air guns fail. It delivers high air volume and strong blowing force for effective cleaning of deep cavities, large surfaces, and stubborn debris.

The High Flow Air Gun is engineered for industrial applications requiring maximum blowing force and extended reach. Unlike conventional air blow guns, this tool is designed to deliver a high volume of compressed air, making it ideal for removing heavy dust, chips, coolant residue, and debris from large or hard-to-reach areas.

Built for continuous industrial use, the gun features a robust construction and an ergonomic trigger mechanism that allows controlled airflow while maintaining operator safety. It is particularly effective in environments where standard blow guns lack the power or reach required to perform efficient cleaning.

This air gun is suited for manufacturing plants, workshops, fabrication units, and maintenance operations where productivity, durability, and performance are critical.

Key Performance Characteristics

-

High air output for powerful blow-off

-

Strong blowing force suitable for industrial cleaning

-

Designed for long-reach and deep-cavity applications

-

Consistent performance under continuous use

Typical Applications

-

Removal of metal chips and heavy dust

-

Cleaning of large machine surfaces

-

Blow-off of coolant and oil residues

-

Deep hole, slot, and cavity cleaning

-

Industrial maintenance and production environments

Operating Conditions

-

Medium: Clean, dry compressed air

-

Operating pressure: Suitable for industrial compressed air systems

-

Designed for high-flow air consumption applications

Available Variants

-

Short length for close-range high-force cleaning

-

Medium length for general industrial use

-

Long length for deep and hard-to-reach areas