Vortex Tube Manufacturers

ACE Flow Konzepts Pvt Ltd is the Simplified Vortex Tube Manufacturers in Maharashtra. Applications of the Vortex Tube are universal and hence it is a solution of choice in industries where spot cooling, localized cooling, or temperature control is necessary. It is used widely in manufacturing facilities to cool sensitive equipment, electrical panels, and machinery that are prone to overheating. It is also used in metalworking industries for cooling tools, blades, and surfaces during cutting, drilling, or grinding to avoid wear and tear caused by heat production. The vortex tube is also used in food processing, medical, and laboratory facilities where temperature-sensitive processes are of utmost importance. Besides industrial uses, it is also used in personal cooling systems to bring comfort to operators who work in extreme conditions.

Vortex Tube Suppliers in Maharashtra

- Operates without mechanical wear, ensuring durability.

- Achieves temperatures as low as -40°F.

- Made from premium materials for harsh industrial environments.

- Suitable for cooling tools, electronics, and workspaces.

- Functions solely using compressed air, no electricity needed.

Vortex Tube in India

With us, you get the Practical Vortex Tube in India. Low maintenance is one of the features that the Vortex Tube has due to its design simplicity and absence of any moving parts. Occasional cleaning from outside to make sure that it is clear from dirt or contaminants is usually the only maintenance needed. As long as the compressed air supply is properly filtered, the vortex tube will operate trouble-free for a long time. Low maintenance not only reduces downtime in operations but also provides a cost-saving measure for industrial facilities with low maintenance budgets.

Vortex tube technology was invented by French physicist Georges Ranque in 1930. Vortex Tubes are devices which generates cold air and hot air by forcing compressed air through a generator. Air enters the vortex tube and is literally split into two parts – cold air at one end, and hot air at the other – all without any moving parts

Vortex Tubes have an adjustable valve at the “hot” end which controls the volume of the air flow, and the temperature exiting at the cold end. By adjusting the valve, you control the “cold fraction” which is the percentage of total input compressed air that exits the cold end of the Vortex Tube. Vortex Tubes may also be supplied with a fixed preset “cold fraction” which can be adjustable later asper customers requirment. Inside is the interchangeable brass “generator” which can alter the air used in the Vortex Tube, and control the temperature ranges you wish to have at the cold and hot ends. There are several ranges of generators for compressed air capacity.

A vortex tube can be made in several sizes the smallest operating with 2 to 8 SCFM and the medium size 10 to 40 SCFM and the large size 50 to 150 SCFM. Larger sizes have rare applications due to high energy consumption.

Vortex tubes generate temperatures as much as 100 deg F (56 deg C) below the inlet air temperature. These Vortex Tubes are used for different purposes and different applications.

Advantages

- No Plastic Products. Generator are made of Brass as compared to plastic Generators of the competitors

- No moving parts

- Driven by air not electricity

- Small and lightweight – portable

- Low in cost compared to most others

- Superior design and performance

- Maintenance free operation

- Made of durable stainless steel and metal parts – no

- Adjustable temperature range

- Generators are interchangeable

Application

- Cooling components and tools

- Cooling at Welding Process and reduce the overheat

- Drying of Components

- Panel Cooling

- CNC System Cooling

- Set hot melt adhesives

- Cool welding horns on ultrasonic

- Cool molded plastics

- Cool Electronic components

- Cool heat shrink tubing

- Keep electronics free of condensation

- Programmable controllers

- System control cabinets

- Motor control centers

- Relay panels

- Environments where cooler panels are near Personnel

- When noise reduction is required

- Laser Housing Cooling

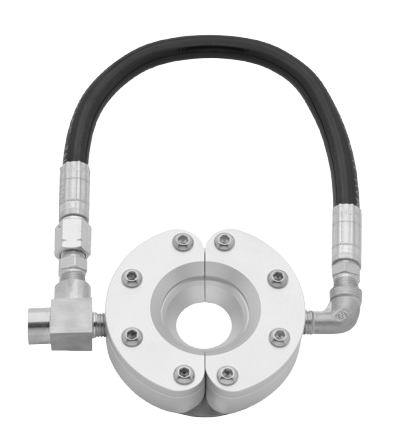

Accessories

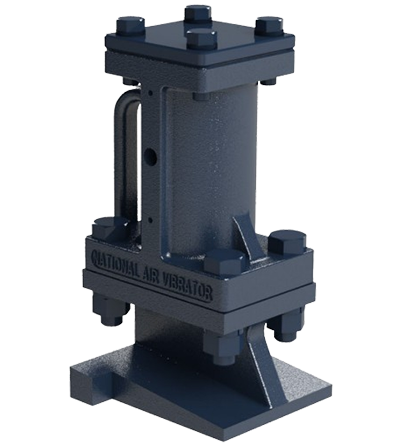

Different Products Made from Vortex Tube

- Panel Cooler

- Tool Cooler

- Spot Cooler

Accessories Related to Vortex Tube:

- Air Filter (recommended)

- Magnetic Base

- Generator

- Silencer Hot End

- Silencer Cold End

- Modular Hose

| Model No. | SCFM | SLPM | BTU/Hr | Watts | Size |

| AIR-M2H | 2 SCFM | 57 SLPM | 145 BTU/Hr.” | 42 W | Small |

| AIR-M4H | 4 SCFM | 113 SLPM | 290 BTU/Hr | 85 W | Small |

| AIR-M8H | 8 SCFM | 227 SLPM | 580 BTU/Hr. | 170 W | Small |

| AIR-M10H | 10 SCFM | 283 SLPM | 730 BTU/Hr. | 214 W | Small |

| AIR-M15H | 15 SCFM | 425 SLPM | 1100 BTU/Hr. | 322 W | Medium |

| AIR-M25H | 25 SCFM | 708 SLPM | 1800 BTU/Hr. | 527 W | Medium |

| AIR-M30H | 30 SCFM | 850 SLPM | 2100 BTU/Hr. | 615 W | Medium |

| AIR-M40H | 40 SCFM | 1133 SLPM | 2900 BTU/Hr. | 849 W | Medium |

| AIR-M50H | 50 SCFM | 1370 SLPM | 3500 BTU/Hr. | 1025 W | Large |

| AIR-M75H | 75 SCFM | 2018 SLPM | 5200 BTU/Hr. | 1523 W | Large |

| AIR-M100H | 100 SCFM | 2700 SLPM | 6900 BTU/Hr. | 12022 W | Large |

| AIR-M150H | 150 SCFM | 4150 SLPM | 10.300 BTU/Hr. | 3018 W | Large |